TLDR Summary

- Why are protective coatings formulators caught between conflicting demands? Specifications now require longer service life (25+ years vs. 15) while regulatory pressures push thinner coating systems — but conventional barrier strategies hit physical limits when you try to do more with less material.

- What changes when you shift from “more barrier pigment” to “smarter barrier architecture”? Coatings can achieve equivalent or better corrosion protection at reduced thickness by using laminar nanomaterials that create disproportionate barrier efficiency and multi-modal protection at ultra-low loadings.

- How does graphene enable next-generation protective coating performance? Graphene’s unique combination of impermeability, mechanical reinforcement, electrical properties, and UV stability creates opportunities for simultaneous barrier, wear resistance, gloss retention, and potentially active corrosion protection in a single additive — opening new performance territory at coating thicknesses previously considered inadequate.

Protective coating specifications are tightening while allowable coating thicknesses are shrinking. Marine systems that once relied on 500-micrometer builds are being pushed toward 250 micrometers for application efficiency and VOC compliance. Infrastructure coatings face 25-year service life requirements with reduced maintenance windows. The traditional response — thicker coatings, more barrier pigment, higher cost — is running out of headroom.

The question facing formulators is straightforward: how do you deliver better protection with less material? And more importantly, what changes in additive strategy make that possible without starting from scratch?

The Impossible Triangle

Every protective coatings formulator recognizes the constraint. You’re being asked to optimize three things simultaneously: extend service life from 15 to 25+ years, reduce coating thickness to meet environmental regulations and application cost targets, and maintain a cost position that doesn’t price you out of the market. With conventional approaches, you can pick two.

This isn’t a future problem. ISO 12944 C5-M category already expects 25-year durability where 15 was previously acceptable. NORSOK M-501 keeps tightening for offshore applications. Infrastructure owners are demanding whole-life cost calculations instead of lowest initial bid. The market has moved, and formulation strategies built around “add more thickness, add more barrier pigment” are hitting physical and economic limits.

The gap becomes obvious when you try to maintain performance while reducing thickness by 40 percent. You can’t simply increase barrier pigment loading by 40 percent — the formulation physics don’t work that way. Beyond about 30-40 percent loading by volume, you start compromising adhesion, flexibility, or creating brittleness. You’re trading one failure mode for another.

This is precisely the constraint that makes nanoscale approaches compelling. When conventional strategies hit loading limits, materials that deliver disproportionate performance at fractional loadings change the equation.

What’s Already Working (And Where New Opportunities Emerge)

Current protective coating technology is genuinely sophisticated. Zinc-rich primers provide sacrificial galvanic protection. Glass flake and micaceous iron oxide create tortuous diffusion paths that slow water, oxygen, and chloride penetration. Epoxy-polyamide chemistries deliver chemical resistance. Polyaspartic topcoats give you UV durability with fast cure times that keep projects on schedule.

These aren’t outdated technologies that need replacing. They’re proven systems with decades of field performance behind them. The opportunity isn’t to abandon what works — it’s to augment it with materials that can contribute performance mechanisms conventional additives can’t deliver.

When specifications demand more from less material, you need additives that operate at a different efficiency curve. This means materials that create barrier effects without occupying the formulation volume that compromises other properties. It means additives that contribute to multiple protection mechanisms simultaneously rather than treating each function separately. And it means addressing the real failure modes that determine long-term performance — not just corrosion resistance but UV degradation, mechanical damage, and gloss retention over years of exposure.

This is where the unique properties of laminar nanomaterials, particularly graphene, create genuine opportunities for performance advancement.

Why Graphene Opens New Performance Territory

Graphene is a single atomic layer of carbon arranged in a hexagonal lattice. What makes it compelling for protective coatings is the combination of properties you get in one material — something that doesn’t exist in conventional barrier pigments.

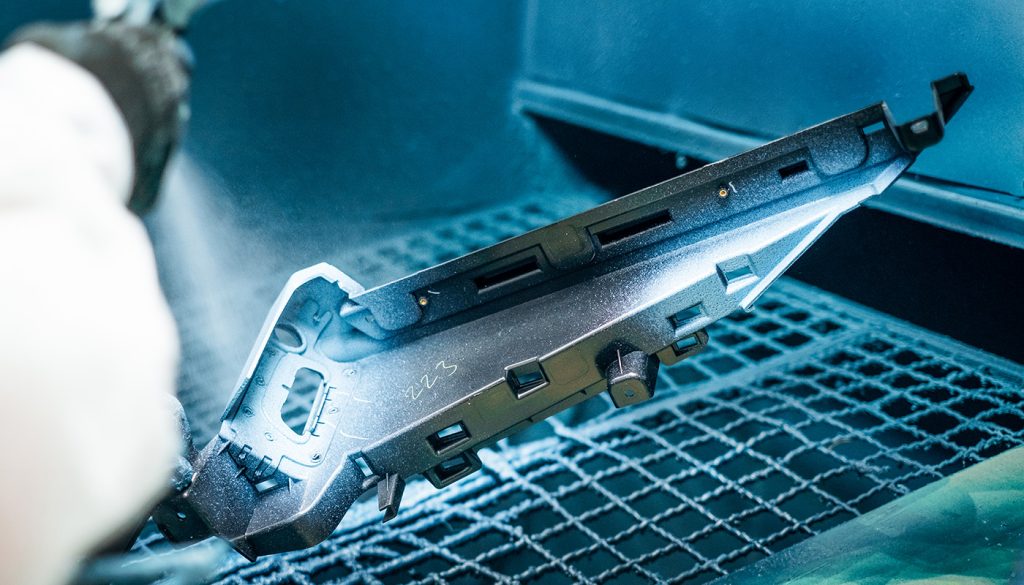

First, graphene platelets are atomically thin but laterally continuous, creating impermeable barriers to water, oxygen, and ionic species. With Fractal Graphene featuring 2-3 nanometer thickness (approximately 6 graphene layers) and lateral dimensions of 20-50 nanometers, these platelets force diffusing species to navigate around them rather than through them. The result is dramatically increased path length for corrosion-driving species to reach the substrate. Studies in peer-reviewed journals like Progress in Organic Coatings and Corrosion Science demonstrate that graphene additions at 0.1 to 0.5 weight percent can improve salt spray resistance by factors of two to five in epoxy and polyurethane systems. Testing shows water-based acrylic coatings formulated with Fractal Graphene achieving over 1200 hours in salt spray exposure with no blistering — performance that would typically require significantly thicker conventional formulations.

Second, graphene brings mechanical reinforcement without brittleness. The pristine carbon structure of Fractal Graphene with 100% sp² hybridization and 99.8% carbon purity provides exceptional tensile strength, which means low loadings can improve scratch and abrasion resistance — the kind of mechanical damage that initiates real-world coating failures. You’re not adding hard particles that create stress concentration points; you’re incorporating reinforcement at the nanoscale that distributes stress more effectively.

Third, graphene demonstrates remarkable UV stability and appears to enhance the UV resistance of the coating matrix itself. Field testing and accelerated weathering studies show that Fractal Graphene-enhanced polyurethane topcoats at just 0.5 weight percent loading maintain 35% better gloss retention after 1000 hours of UV exposure compared to control formulations. This is particularly valuable for protective coatings where appearance degradation often drives recoating decisions even when the underlying corrosion protection remains functional. The ability to extend both aesthetic and protective performance simultaneously addresses a major challenge in architectural, marine, and transportation coatings where visual appeal and durability must both endure years of UV exposure.

Fourth, and perhaps most interesting for next-generation systems, graphene conducts electricity. Unlike inert barrier pigments, this creates possibilities for localized electrochemical effects at defect sites. While the mechanisms are still being explored in the literature, the potential for graphene to contribute to active corrosion protection — not just passive barrier — represents genuinely new territory for protective coatings.

The key insight is that you’re not choosing between barrier performance, mechanical properties, UV resistance, or functional responsiveness. Graphene delivers all four from a single additive at loadings that leave plenty of formulation headroom for other components.

The Material Efficiency Advantage

What excites formulators about graphene is the efficiency equation. Conventional barrier pigments require substantial loading to create effective tortuosity — often 15-30 percent by volume. That loading level constrains everything else in the formulation. Rheology becomes difficult to control. Adhesion can suffer. You lose flexibility. The formulation becomes increasingly brittle.

Graphene operates at an entirely different loading regime. From as low as 0.1 weight percent, Fractal Graphene creates defect-free barrier networks that prevent permeation of corrosive media while preserving coating flexibility, adhesion, and application properties. This is 10 to 100 times lower than conventional barrier fillers that compromise mechanical performance at high loadings. The fractal aggregate structure composed of nanoscale primary particles provides maximum barrier efficiency with minimal impact on coating characteristics, leaving formulation space for all the other components that deliver the complete performance profile you need — adhesion promoters, flow modifiers, UV stabilizers, whatever your specific application demands.

The efficiency advantage compounds when you consider multi-modal protection. A conventional formulation might use separate additives for barrier properties, scratch resistance, UV stability, and corrosion inhibition. Each takes up formulation space. Each potentially creates compatibility challenges. Graphene consolidates several of these functions, which means you’re not just adding performance — you’re potentially simplifying the additive package while improving results.

This is particularly valuable when coating thickness is constrained. If you’re being pushed to 200 micrometers where you previously used 350, you can’t just scale down the entire formulation proportionally. Performance doesn’t work that way. You need additives that deliver more protection per unit thickness, and that’s exactly where graphene’s efficiency profile creates opportunity.

Where Graphene Fits Your Formulation Strategy

The strategic opportunity for graphene becomes clear when you map it against current protective coating challenges. If you’re reformulating to meet tightening VOC regulations that force thinner systems, graphene helps maintain or improve performance at reduced thickness. If you’re developing premium product lines where customers pay for extended service life, graphene creates differentiation that’s measurable in standard test methods — salt spray hours, electrochemical impedance, abrasion resistance, and QUV weathering performance.

If you’re facing performance failures in current systems — premature corrosion breakthrough, mechanical damage sensitivity, adhesion loss under cyclic exposure, or gloss degradation that triggers early recoating — graphene provides additional tools that conventional additives don’t offer. The combination of barrier enhancement, mechanical reinforcement, UV stability, and potential electrochemical activity addresses multiple failure modes simultaneously.

The applications that benefit most are those where coating performance genuinely matters to the bottom line. Offshore structures and marine infrastructure where coating failure means expensive maintenance shutdowns. Pipelines and storage tanks where integrity is critical. Bridges and civil infrastructure where recoating requires lane closures or service interruptions. Industrial equipment, chemical processing facilities, and power generation assets where downtime is costly. Architectural applications where gloss retention determines the effective service life. These are environments where the performance-per-micrometer equation matters more than cost-per-gallon, and that’s where graphene’s value proposition is strongest.

Graphene works across the major resin systems used in demanding protective applications — epoxy, polyurethane, acrylic, alkyd, and polyester chemistries. It’s compatible with standard application methods including spray applications (airless, electrostatic, HVLP), brush and roller application, dip coating, and even powder coating systems.

Even in more cost-sensitive markets, the equation can work if you’re reducing coating thickness while maintaining specification performance. Less material used, faster application, lower VOC emissions — the economics change when you account for the full application cost, not just formulation cost.

Making Graphene Work: What Actually Matters

The difference between graphene that performs and graphene that disappoints comes down to quality and integration. High-quality material features pristine carbon structure — the kind that comes from 100% sp² hybridization with minimal oxygen content and no polycyclic aromatic hydrocarbons. Fractal Graphene, for example, contains 99.8% carbon and only 0.2% oxygen with no PAHs, ensuring consistent performance without the contamination issues that plague lower-quality graphene materials. Surface chemistry matters for specialized applications, with functionalized versions like Reactive Graphene featuring carboxylic acid groups available for enhanced compatibility in specific resin systems.

Dispersion is where many first attempts stumble. Graphene at the nanoscale has high surface energy and wants to reaggregate. Getting stable, uniform dispersion requires appropriate mixing energy, often dispersing aids, attention to the sequence of addition in your formulation — or receiving the material pre-dispersed in a compatible carrier system that eliminates the dispersion challenge entirely. The good news is that whether you’re developing in-house dispersion protocols or working with pre-dispersed concentrates, once you establish a process that works for your resin chemistry and equipment, it’s reproducible. This isn’t mysterious art — it’s process development like any other formulation work.

Material consistency matters tremendously. Batch-to-batch variation can destroy reproducibility in formulation development. High-quality graphene suppliers provide identical consistency from batch to batch, with controlled particle size uniformity and exceptional purity that ensures predictable performance. When you’re working at 0.1 to 0.5 weight percent loadings, you need confidence that every batch will deliver the same results.

The formulators seeing the best results are working with suppliers who provide more than just material — application engineering support, dispersion protocols specific to protective coatings, pre-dispersed solutions that simplify integration, and characterization data that goes beyond surface-level spec sheets. Quality matters more than price when you’re working at sub-one-percent loadings. The cost difference between mediocre graphene and excellent graphene is negligible on a per-formulation basis, but the performance difference is substantial.

The Opportunity Ahead

The protective coatings market is evolving toward performance-based differentiation. With corrosion causing 3-4% of global GDP losses annually, the pressure to deliver breakthrough protection that extends asset life and dramatically reduces maintenance cycles has never been greater. Commodity products will always exist, but the growth opportunity is in systems that deliver measurably better protection, longer service life, and lower total cost of ownership. Graphene positions you to compete in that space.

The material isn’t a replacement for everything you’re currently doing — it’s an enhancement that makes existing resin systems perform better. You’re not abandoning proven epoxy or polyurethane chemistry; you’re giving those systems new capabilities through a functional additive that operates at a different efficiency level than conventional barrier pigments.

What makes this particularly compelling is the timing. Specifications are tightening now. Coating thickness requirements are shrinking now. Environmental regulations are forcing reformulation now. The formulators who develop expertise with advanced nanomaterials while these transitions are happening will have competitive advantages that become harder to replicate as the market matures.

The research foundation is solid — hundreds of peer-reviewed papers demonstrating the mechanisms and performance benefits. The commercial applications are expanding — protective coatings companies are launching graphene-enhanced products for marine, infrastructure, and industrial segments. The supply chain is maturing — quality material is becoming more accessible with better supplier support, pre-dispersed solutions that reduce technical barriers to adoption, and the sustainability advantage of materials produced with the lowest energy and carbon footprint available.

The question isn’t whether graphene works in protective coatings. The testing data and commercial deployments demonstrate it does. The question is whether you’re positioned to take advantage of what it enables — thinner systems with better performance, premium products with measurable differentiation, formulations that address multiple failure modes with a single additive.

For formulators looking at the next three to five years of product development, graphene represents one of the most promising opportunities to deliver performance that simply wasn’t accessible with conventional approaches. The material is ready. The question is whether your product roadmap is.