Thermoplastics - Graphene Applications for Stronger, More Durable, Lightweight Components

Graphene compounded into thermoplastics enhances mechanical properties, thermal and electrical conductivity, moisture and gas barrier performance, whilst maintaining or improving processability.

MARKET OVERVIEW

The thermoplastic industry encompasses a wide range of polymer materials that can be repeatedly melted and reformed, including polyethylene (PE), polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and engineering plastics like polyamide/nylon (PA), polycarbonate (PC), and polyetheretherketone (PEEK).

$650 BILLION MARKET SIZE

Compounding plastics involves blending these base polymers with additives, fillers, reinforcements, and modifiers to enhance specific properties and create customized materials for targeted applications. These versatile materials are converted through a variety of melt processes including injection molding, profile and sheet extrusion, fibre spinning, blow molding, rotomolding, thermoforming, 3D printing, to create products with specific performance characteristics tailored to demanding applications.

The thermoplastic industry serves diverse sectors and applications, including:

- Automotive Components

- Electronics and Electrical

- Packaging and Consumer Goods

- Medical and Healthcare

- Construction and Building

- Aerospace and Defense

- Industrial Equipment

Features and Benefits of Thermoplastic Compounds with Graphene

Significantly improves tensile strength, modulus, and toughness, increasing plastic performance by 20% to 70% while maintaining processability.

Dramatically increases thermal conductivity, enabling better heat dissipation in electronic housings, automotive components, and industrial applications where thermal management is critical.

Provides tunable electrical properties from anti-static to conductive, enabling EMI shielding, static dissipation, and smart material applications in electronics and automotive sectors.

Creates tortuous pathways that significantly reduce gas and moisture permeability, enhancing shelf life and protection in packaging applications.

Reduces thermal expansion and shrinkage during processing, resulting in improved dimensional accuracy and reduced warping in precision-molded components.

Improves surface hardness, scratch resistance, and wear properties while maintaining the aesthetic qualities required for consumer and automotive applications.

Maintains excellent melt flow characteristics and processability, allowing for standard thermoplastic processing equipment without significant modifications.

Enables lightweighting and material reduction while maintaining or improving performance, contributing to lower carbon footprint and reduced material costs.

HydroGraph’s Pristine Turbostratic Graphene in Action

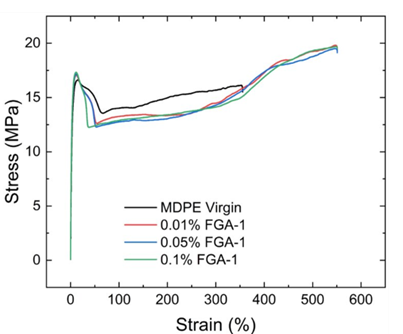

30% Increase in Strength at Break

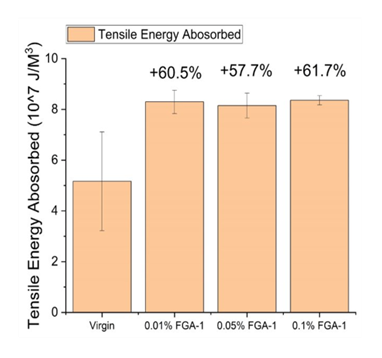

60% Increase in Toughness