Graphene

- Home

- /

- Graphene

Graphene

Graphene is a “super-material” stronger than steel, harder than diamond, more conductive than copper, with better electron mobility than silicon.

Reactive Shell Graphene

As a material additive, our unique reactive shell graphene can chemically combine with other products, a superior bonding process to the competitors.

Graphene Ink

This new and novel form of “conductive ink” maintains the valuable qualities of graphene including strength, non-toxicity, flexibility, and optical transparency.

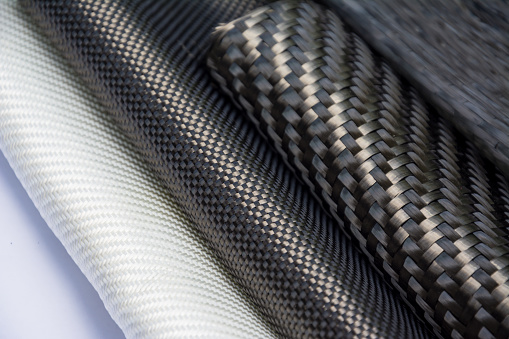

Graphene Enhanced Carbon Fiber

Our graphene used in 3D Printing enables the creation of lighter, stronger parts and systems and can produce objects at a lessor expense than traditional manufacturing.

Graphene is a “super-material” poised to explode in the commercial market.

WHAT IS GRAPHENE?

Graphene markets are almost limitless

Graphene, a “super-material” poised to explode in the commercial market, is stronger than steel, harder than diamond, more conductive than copper, with better electron mobility than silicon. Its markets and applications are almost limitless — the product is added to other materials to enhance strength, water resistance, flexibility, electrical conductivity; and it supports clean energy by improving battery, solar panel and supercapacitor technology. Here are a few of the addressable markets for graphene. (Source: Grandview research)

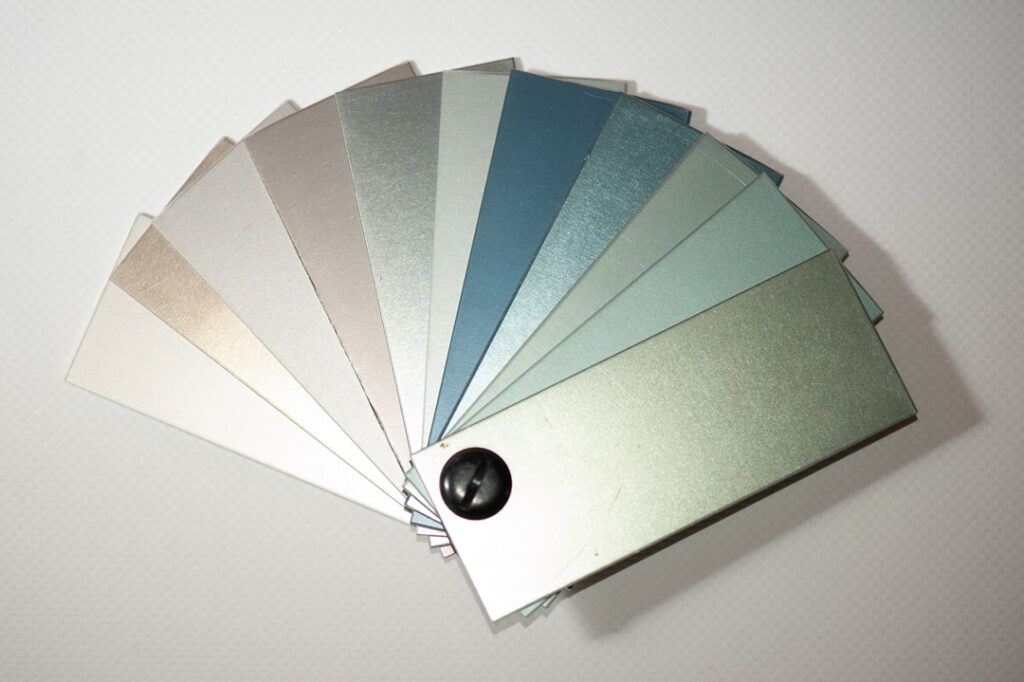

COATINGS

Overall, the global industrial coatings market was estimated at $83B in 2020, and is expected to expand at a rate of 3.4% (CAGR) through 2029.

LUBRICANTS

At $128B in 2020 with an expected growth of 3.7% (CAGR) through 2028, the demand for higher performance lubricants continues to grow.

RESINS

The thermoplastic resin market is expected to reach $13B by 2026, as these resins are 30%-40% lighter than aluminum with a high heat tolerance and fatigue resistance.

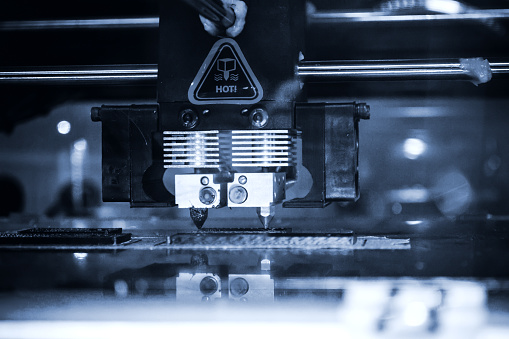

3D PRINTING

In 2021, the 3D printing sector reached $10.6B revenue, excluding hardware maintenance contracts and post-processing equipment, with AM is expected at over $50 billion by 2030.

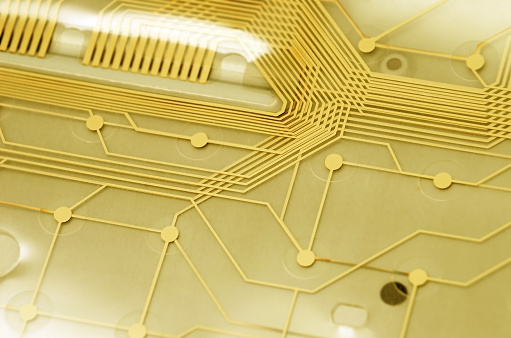

PRINTED ELECTRONICS

The global market for printed electronics — printing methods used to create electrical devices — was estimated at $8.6B in 2021 with 22.3% growth (CAGR) through 2030

BIOSENSORS

The global biosensors (biological sensor) market size was valued at $24.9B in 2021 and is expected to expand at 8% (CAGR) from 2022 to 2030.

COMPOSITES

The market for global composites — a material made from two or more materials — was estimated at $86.4B in 2020 with growth of 6.6% (CAGR) through 2028

Learn More >>

Read the HydroGraph investor deck to learn how our products and go-to-market strategy will deliver value for customers and investors.

HydroGraph graphene products

Patent Title: "Graphene/Graphene Oxide Core/Shell Particulates and Methods

of Making and Using the Same"

REACTIVE SHELL GRAPHENE

HydroGraph’s functionalized graphene – benefitting from an advanced graphene production method and produced at industrial scale – offers greater versatility and potential than conventional graphene at a time of skyrocketing demand. It’s “reactive,” because it can chemically combine with other materials, rather than being simply mixed as is conventional graphene produced through other methods. The chemical combination is enabled through its reactive shell, with a surface of carboxylic acid groups and an interior that remains uncompromised.

Reactive graphene is a derivative material of HydroGraph’s Fractal Graphene and possesses a host of attractive properties, such as high electrical conductivity. It has applications in a vast number of areas, including: Energy storage; Lithium batteries; Supercapacitors; Solar cells; Medicine and biology.

Patent Title: "Nano-inks of Carbon Nanomaterials for Printing and Coating"

GRAPHENE INK

Our patented graphene ink is an entirely new and novel form of “conductive ink” that maintains the valuable qualities of graphene including strength, non-toxicity, flexibility, and optical transparency. As the name suggests, conductive ink is a material that conducts energy with the utility of an ink. Our unique graphene ink technology with enhanced performance characteristics and fewer production barriers is covered in the “Nano-inks of Carbon Nanomaterials for Printing and Coating” patent.

This development marks a significant step toward the production of inexpensive, foldable, and wearable electronics. Our highly competitive cost and mass production method for high quality graphene opens up a wealth of opportunity for the practical applications of conductive ink patterns. Markets include touch screen displays, biosensors, radio frequency identification tags, electric vehicle batteries, and more. With growing possibilities for printed electronics every day, the need for conductive inks like graphene ink is on the rise.

Patent Title: "Additive Manufacturing of Continuous Fiber Thermoplastic Composites"

GRAPHENE ENHANCED

CARBON FIBER

Our “Additive Manufacturing of Continuous Fiber Thermoplastic Composites” patent, licensed to HydroGraph from KSU, provides for the company’s superior graphene to be used in 3D-printing. Carbon Additive Manufacturing (CAM) is a 3D-printing process that has carbon as the additive element. It enables the creation of lighter, stronger parts and systems and can produce objects at a lessor expense than traditional manufacturing.

Additive manufacturing (3D printing) is quickly revolutionizing manufacturing and is estimated to be a $4B industry by 2030. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries and simplified fabrication. Its current applications include: Engineering resins; aerospace; automotive; medical; industrial; manufacturing; sports equipment ; and athletic footwear